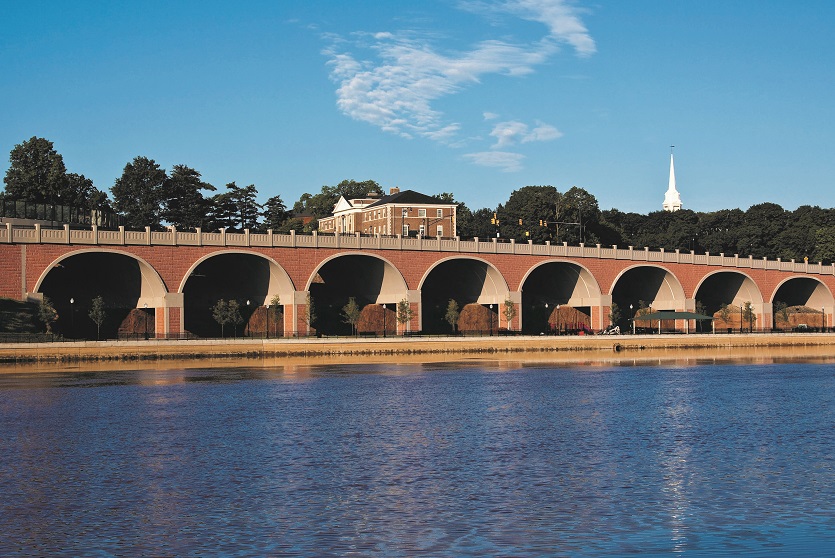

As a result of comprehensive research and development carried out by Terre Armée, TechSpan® was launched in 1989.

This optimal solution provides builders with a state-of-the-art three hinge segmental precast concrete arch system for building short to medium span earth-overfilled bridging structures.

Applications

Now a matured choice for engineers, TechSpan® arches are built for:

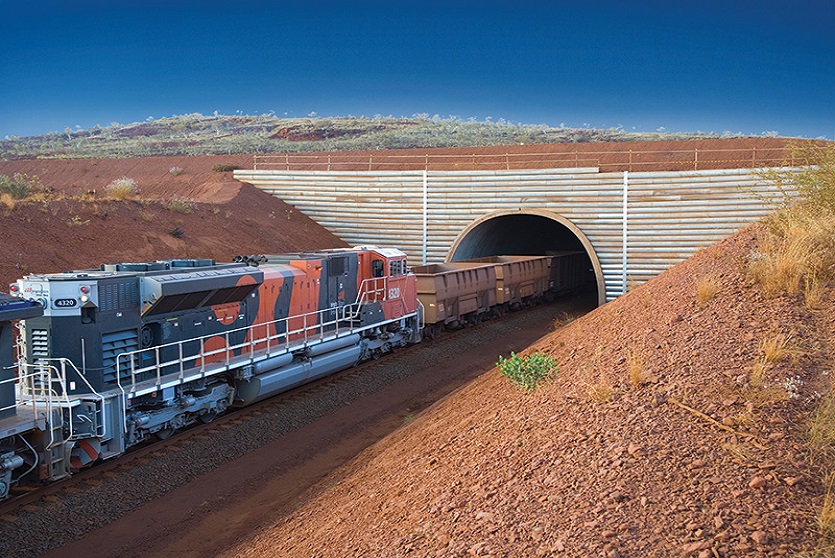

- Roadway and railway bridge underpass, overpass and covered tunnels

- Explosives and munitions storage facilities for military and industry

- Industrial reclaim conveyor tunnels and escape routes

- Commercial and pedestrian overfilled passages

- Rockfall protection sheds and galleries

- Pedestrian passage and animal crossings

Optimized design procedure

The TechSpan® solution, while sophisticated in terms of design is simple for planners and builders to incorporate into their projects. These structures are designed to accommodate high fills, heavy live loads, as well as alternating loading conditions imposed during both installation and in service conditions.

Each TechSpan® structure is specifically designed, structurally and geometrically for your application. Finite element model analysis design (FEM) accurately defines the optimal radius of curvature of the arch to minimize tensile stresses. Our approach results in slender concrete sections with optimized reinforcement for maximum safety in design and construction, with long service life at the lowest possible cost to the builder and end user.

Optimized manufacturing processes

Using our unique flexible concrete precasting formwork and quality-controlled casting process results in finished elements that conform to any and all geometric and material quality specifications.

Our design and material supply package often includes materials required to construct the necessary retaining structures for wing walls and spandrels, and also other precast solutions including footings, copings, barriers and slip joints.

Optimized installation procedures

Requiring only a narrow footprint to build, TechSpan® installation is simple, rapid and predictable requiring only a small work crew, light tools and conventional equipment. Erection rates of 10 to 20 linear meters of arch per shift are easily possible with only a single crane with operator, while the use of two cranes with operator will speed production at the initial start of installation.

The TechSpan® solution eliminates the need for intensive onsite formwork, scaffolding, joints or bearings. Installation over active roadways, railways, waterways and conveyance systems is possible without disruption to the ongoing activity.

The abbreviated installation procedure consists of the following steps:

- Establishing keyway foundations

- Receiving and arranging arch segments

- Segment placement by crane(s)

- Grouting of segments into the keyway

- Pouring of a crown beam or stitch joint

- Applying joint cover or waterproofing

- Backfilling per approved guidelines and specifications

Benefits

Durability

Durability

The inherent durability of quality precast concrete provides a long service life with minimal maintenance requirements.

Cost savings

Cost savings

As opposed to alternatives, the cost savings using TechSpan® increase as the fill height imposed on the arches increases.

Full scope of services

Full scope of services

A full scope of services, from inception to completion:

- Feasibility studies and estimates

- P.E. sealed designs and calculations

- Manufacturing and delivery of materials

- Onsite technical assistance

- Instrumentation and monitorization

Solution bundling

Solution bundling

Designs and materials for headwalls, wing walls and collars are conveniently included in the Terre Armee material supply package.

Do you have a project? Fill in the form to contact our experts…